Finsbury Food Group provide bakery products to the UK retail and foodservice market. They are key supplier to several licensed brands including Disney, Thorntons and Village Bakery.

As a food processor, temperature control for storage and processing of raw materials and ingredients is acritical part of the process. Three product chilling zones within the company’s manufacturing facility where temperature monitoring was still conducted manually, left the site exposed to risk should the temperature checks be missed or delayed.

aquidataxl was engaged to design, build and install a temperature monitoring solution to mitigate the risk associated with any failure or delay in checking the readings.

aquidataxl provided a smart solution that integrated into the existing equipment and plant layout. Reliability is key and the wireless system that was selected needed to be able to transmit through the building therefore the building construction was reviewed and on-site testing was required.

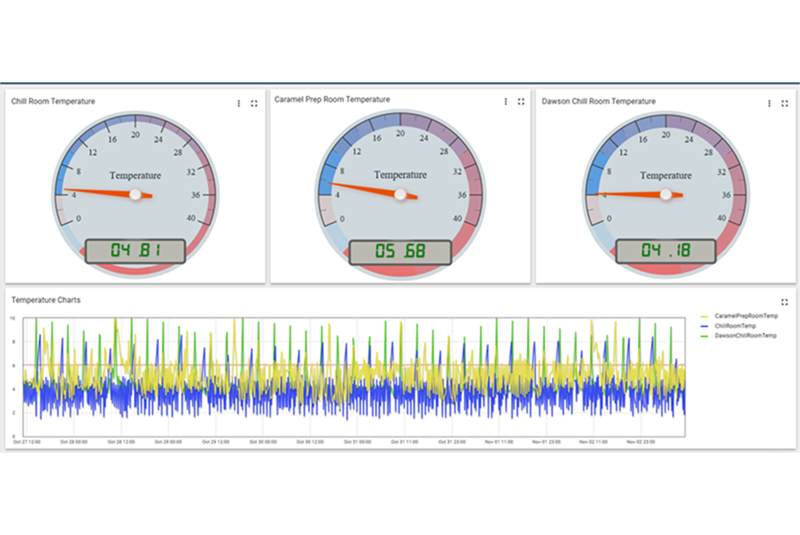

The system installed provides ongoing real time monitoring of the temperatures within each of the designated areas. Pre-determined high and low alarm points have been configured and should the temperature deviate from these parameters for a given time period, system operators are sent alerts so that they can investigate and action immediately.

The hardware and software integrated into this solution were designed to meet the client specification, information gathering, management and reporting has now been automated and become a continuous process reducing the risk to production.

Alarms are raised and notifications made through a variety of methods improving visibility and the response times to correct any issues. Visualisation is done on a fully configured dashboard customised to the exact client specification with historical information which enables performance reports to be generated for each of the chilling zones.

The aquidataxl solution keeps the operator informed of asset performance and also influences maintenance by introducing anomaly detection and predicting future performance, minimising downtime and thereby allowing significant cost savings and improved efficiency.

Ross Begley, Site Engineering lead for Finsbury Food Group, said:

“aquidataxl provided a complete turn-key solution which exceeded expectations from a technical standpoint. The team at XL ensured that all key stakeholders were engaged and thorough in their approach. We are now looking at how we can continue to use aquidataxl in other areas of manufacturing to protect our assets.”